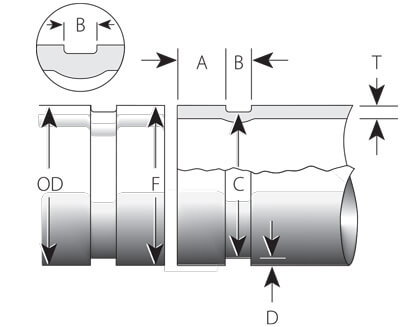

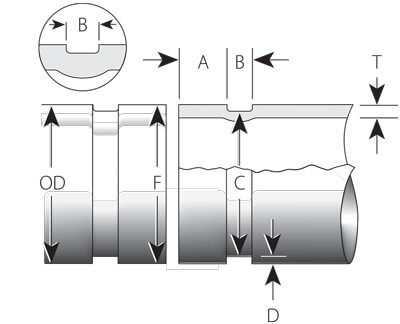

Dimension of roll grooved end

Roll groove is suitable for steel pipes with standard and light thickness. It has advantage of without removing any pipe material. At present, most of the grooved pipes use roll grooving due to the simplicity of the grooving process and maximum joint performance. It follows standards AWWA C606 and ISO 6182.

However, roll groove shall cause the inner wall of the steel pipe to be raised because of extrusion of roll grooving machine, and it may also result in unacceptable pipe end flare. See Max flaring diameter (F) as below chart.

Roll groove as ANSI/AWWA C606

| Nominal size | Pipe OD | Min wall Thickness (T) | Gasket seat (A) -0.76/+0.38 | Groove width (B) -0.38/+0.76 | Groove diameter (C) | Groove depth (D) | Max flaring diameter (F) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Tolerance (mm) | Average | Tolerance +0.00 | ||||||||

| Inch | DN | mm | - | + | mm | mm | mm | mm | mm | mm | mm |

| 1" | 25 | 33.4 | 0.33 | 0.33 | 1.65 | 15.88 | 7.14 | 30.23 | -0.38 | / | / |

| 1-1/4" | 32 | 42.2 | 0.41 | 0.41 | 1.65 | 15.88 | 7.14 | 38.99 | -0.38 | / | / |

| 1-1/2" | 40 | 48.3 | 0.48 | 0.48 | 1.65 | 15.88 | 7.14 | 45.09 | -0.38 | / | / |

| 2" | 50 | 60.3 | 0.61 | 0.61 | 1.65 | 15.88 | 8.74 | 57.15 | -0.38 | / | / |

| 2-1/2" | 65 | 73.0 | 0.74 | 0.74 | 2.11 | 15.88 | 8.74 | 69.09 | -0.38 | / | / |

| 3" | 80 | 88.9 | 0.79 | 0.89 | 2.11 | 15.88 | 8.74 | 84.94 | -0.38 | / | / |

| 4" | 100 | 114.3 | 0.79 | 1.14 | 2.11 | 15.88 | 8.74 | 110.08 | -0.38 | / | / |

| 5" | 125 | 141.3 | 0.79 | 1.42 | 2.77 | 15.88 | 8.74 | 137.03 | -0.38 | / | / |

| 6" | 150 | 168.3 | 0.79 | 1.60 | 2.77 | 15.88 | 8.74 | 163.96 | -0.38 | / | / |

| 8" | 200 | 219.1 | 0.79 | 1.60 | 2.77 | 19.05 | 11.91 | 214.40 | -0.51 | / | / |

| 10" | 250 | 273.1 | 0.79 | 1.60 | 3.40 | 19.05 | 11.91 | 268.27 | -0.64 | / | / |

| 12" | 300 | 323.9 | 0.79 | 1.60 | 3.96 | 19.05 | 11.91 | 318.29 | -0.64 | / | / |

Note:

1. Pipe OD: The outside diameter of roll grooved pipe.

2. Min wall thickness (T): This is the minimum allowable pipe wall thickness which could be roll grooved.

3. Gasket seat (A): It is measured from the pipe end to groove, for gasket seating.

4. Groove width (B): It shall be free of scale, dirt, chips, and rust that may interfere with proper coupling assembly.

5. Groove diameter (C): It shall be uniform groove diameter for the entire pipe circumference.

6. Groove depth (D): It is measured from pipe outer surface to groove outer surface.

7. Max flare diameter (F): It is maximum allowable pipe end flaring diameter.

2. Min wall thickness (T): This is the minimum allowable pipe wall thickness which could be roll grooved.

3. Gasket seat (A): It is measured from the pipe end to groove, for gasket seating.

4. Groove width (B): It shall be free of scale, dirt, chips, and rust that may interfere with proper coupling assembly.

5. Groove diameter (C): It shall be uniform groove diameter for the entire pipe circumference.

6. Groove depth (D): It is measured from pipe outer surface to groove outer surface.

7. Max flare diameter (F): It is maximum allowable pipe end flaring diameter.

Roll groove as ISO 6182-12

| Nominal size | Pipe OD | Min wall Thickness (T) |

Gasket seat (A) ±0.76 | Groove width (B) ±0.76 | Groove diameter (C) | Groove depth (D) | Max flaring diameter (F) |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Tolerance (mm) | Actual | Tolerance +0.00 | ||||||||

| Inch | DN | mm | - | + | mm | mm | mm | mm | mm | mm | mm |

| 1" | 25 | 33.7 | 0.33 | 0.33 | 1.65 | 15.88 | 7.14 | 30.23 | -0.38 | 1.73 | 36.3 |

| 1-1/4" | 32 | 42.4 | 0.41 | 0.41 | 1.65 | 15.88 | 7.14 | 38.99 | -0.38 | 1.70 | 45.0 |

| 1-1/2" | 40 | 48.3 | 0.48 | 0.48 | 1.65 | 15.88 | 7.14 | 45.09 | -0.38 | 1.60 | 51.1 |

| 2" | 50 | 60.3 | 0.61 | 0.61 | 1.65 | 15.88 | 8.74 | 57.15 | -0.38 | 1.57 | 63.0 |

| 2-1/2" | 65 | 73.0 | 0.74 | 0.74 | 2.11 | 15.881 | 8.742 | 69.09 | -0.46 | 1.95 | 75.7 |

| 2-1/2" | 65 | 76.1 | 0.76 | 0.76 | 2.11 | 15.88 | 8.74 | 72.26 | -0.46 | 1.92 | 78.7 |

| 3" | 80 | 88.9 | 0.79 | 0.89 | 2.11 | 15.88 | 8.74 | 84.94 | -0.46 | 1.98 | 91.4 |

| 4" | 100 | 114.3 | 0.79 | 1.14 | 2.11 | 15.88 | 8.74 | 110.08 | -0.51 | 2.11 | 116.8 |

| 5" | 125 | 139.7 | 0.79 | 1.42 | 2.77 | 15.88 | 8.74 | 135.48 | -0.51 | 2.11 | 142.2 |

| 5" | 125 | 141.3 | 0.79 | 1.42 | 2.77 | 15.881 | 8.742 | 137.03 | -0.38 | 2.13 | 143.8 |

| 6" | 150 | 165.1 | 0.79 | 1.60 | 2.77 | 15.88 | 8.74 | 160.78 | -0.56 | 2.16 | 167.6 |

| 6" | 150 | 168.3 | 0.79 | 1.60 | 2.77 | 15.881 | 8.742 | 163.96 | -0.56 | 2.17 | 170.9 |

| 8" | 200 | 219.1 | 0.79 | 1.60 | 2.77 | 19.05 | 11.91 | 214.4 | -0.64 | 2.35 | 223.5 |

| 10" | 250 | 273.0 | 0.79 | 1.60 | 3.40 | 19.05 | 11.91 | 268.28 | -0.69 | 2.36 | 277.4 |

| 12" | 300 | 323.9 | 0.79 | 1.60 | 3.96 | 19.05 | 11.91 | 318.29 | -0.76 | 2.80 | 328.2 |

Note:

1. 1 means A tolerance is +0.38/-0.76, not ±0.76.

2. 2 means B tolerance is +0.76/-0.38, not ±0.76.

2. 2 means B tolerance is +0.76/-0.38, not ±0.76.