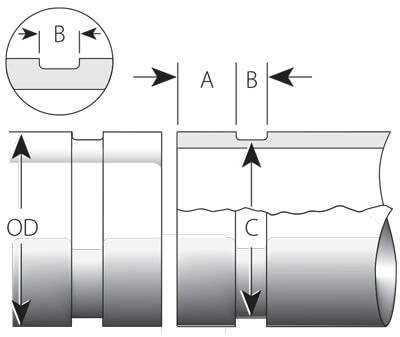

Dimension of cast grooved end

To raise efficiency, many factories take the method of cast groove for small size grooved pipe fittings and couplings, normally below 8″ (DN200). It follows standard ISO 6182-12, and no related AWWA standard.

Cast groove as ISO 6182-12

| Nominal size | Outside diameter | Gasket seat (A) ±0.76 |

Groove width (B) ±1.17 |

Groove diameter (C) | ||||

|---|---|---|---|---|---|---|---|---|

| OD | Tolerance (mm) | Average | Tolerance +0.00 | |||||

| Inch | DN | mm | - | + | mm | mm | mm | mm |

| 1" | 25 | 33.4 | 0.37 | 0.37 | 15.88 | 7.54 | 30.2 | -0.89 |

| 1-1/4" | 32 | 42.2 | 0.37 | 0.37 | 15.88 | 7.54 | 39.0 | -0.89 |

| 1-1/2" | 40 | 48.3 | 0.34 | 0.34 | 15.88 | 7.54 | 45.1 | -0.89 |

| 2" | 50 | 60.3 | 0.40 | 0.40 | 15.88 | 8.36 | 57.2 | -0.89 |

| 2-1/2" | 65 | 73.0 | 0.49 | 0.49 | 15.88 | 8.36 | 69.1 | -0.97 |

| 2-1/2" | 65 | 76.1 | 0.50 | 0.50 | 15.88 | 8.36 | 72.3 | -0.97 |

| 3" | 80 | 88.9 | 0.54 | 0.54 | 15.88 | 8.36 | 84.9 | -0.97 |

| 4" | 100 | 114.3 | 0.61 | 0.61 | 15.88 | 9.14 | 110.1 | -1.07 |

| 5" | 125 | 139.7 | 0.68 | 0.68 | 15.88 | 9.14 | 135.5 | -1.07 |

| 5" | 125 | 141.3 | 0.69 | 0.69 | 15.88 | 9.14 | 137.0 | -1.07 |

| 6" | 150 | 165.1 | 0.74 | 0.74 | 15.88 | 9.14 | 160.8 | -1.07 |

| 6" | 150 | 168.3 | 0.74 | 0.74 | 15.88 | 9.14 | 164.4 | -1.07 |

| 8" | 200 | 219.1 | 0.76 | 0.76 | 19.05 | 11.53 | 214.4 | -1.52 |

| 10" | 250 | 273.0 | 0.77 | 0.77 | 19.05 | 12.32 | 268.3 | -1.57 |

| 12" | 300 | 323.9 | 0.79 | 0.79 | 19.05 | 12.32 | 318.3 | -1.65 |

Note:

1. OD: The outside diameter of cast grooved component.

2. Gasket seat (A): It is measured from the component end to groove, for gasket seating.

3. Groove width (B): It shall be free of scale, dirt, chips, and rust that may interfere with proper coupling assembly.

4. Groove diameter (C): It shall be uniform groove diameter for the entire component circumference.

2. Gasket seat (A): It is measured from the component end to groove, for gasket seating.

3. Groove width (B): It shall be free of scale, dirt, chips, and rust that may interfere with proper coupling assembly.

4. Groove diameter (C): It shall be uniform groove diameter for the entire component circumference.