BSPP, BSPT and NPT thread

Threaded connection plays an important role in pipe connection and seal where conveys liquids, gases and steam. Till today, in threaded connection world it is governed by 2 kinds — British Standard Pipe Thread (BSP) and National pipe tapered (NPT).

BSP was created by British engineer Joseph Whitworth in 1841 that are widely used in Europe, Africa and most Asian coutries.

NPT was invented several years later in 1864 by American engineer William Sellers which are applicable in American countries.

BSP

BSP includes BSPP (British Standard Pipe Parallel) and BSPT (British Standard Pipe Taper).

BSPP

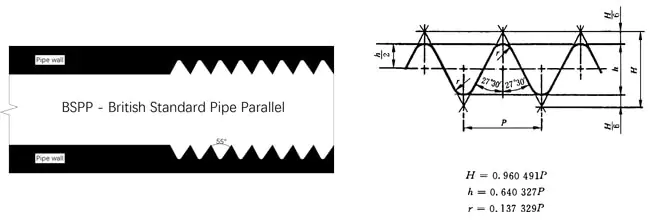

British Standard Pipe Parallel Thread (BSPP) has been adopted internationally as a standard scale used in plumbing fittings, and it is defined by BS EN 10226-1 and ISO 7-1, or ISO 228-1 (GB/T 7306.1, GB/T 7307).

BSPP thread has Whitworth thread form (rounded peaks and valleys) with thread angle 55°.

It is designated for both pressure-tight connection (Rp x R1) or not pressure-tight connection (G x G).

BSPP thread has Whitworth thread form (rounded peaks and valleys) with thread angle 55°.

It is designated for both pressure-tight connection (Rp x R1) or not pressure-tight connection (G x G).

BSPP (Rp) thread dimension

| Pipe size | Thread number in 25.4mm | Thread pitch (P) | Thread height (h) | Diameter at gauge plane | Tolerance on position of gauge plane on internal thread * | ||||

|---|---|---|---|---|---|---|---|---|---|

| Major gauge diameter (d=D) | Pitch (d₂=D₂) | Minor (d₁=D₁) | Tolerance ±T₂/2 | ||||||

| (inch) | (mm) | (no.) | (mm) | (mm) | (mm) | (mm) | (mm) | (inch) | Turns of thread |

| 1/4" | 13.5 | 19 | 1.337 | 0.856 | 13.157 | 12.301 | 11.445 | 1.7 | 1 1/4 |

| 3/8" | 17.2 | 19 | 1.337 | 0.856 | 16.662 | 15.806 | 14.950 | 1.7 | 1 1/4 |

| 1/2" | 21.3 | 14 | 1.814 | 1.162 | 20.955 | 19.793 | 18.631 | 2.3 | 1 1/4 |

| 3/4" | 26.9 | 14 | 1.814 | 1.162 | 26.441 | 25.279 | 24.117 | 2.3 | 1 1/4 |

| 1" | 33.7 | 11 | 2.309 | 1.479 | 33.249 | 31.77 | 30.291 | 2.9 | 1 1/4 |

| 1-1/4" | 42.4 | 11 | 2.309 | 1.479 | 41.910 | 40.431 | 38.952 | 2.9 | 1 1/4 |

| 1-1/2" | 48.3 | 11 | 2.309 | 1.479 | 47.803 | 46.324 | 44.845 | 2.9 | 1 1/4 |

| 2" | 60.3 | 11 | 2.309 | 1.479 | 59.614 | 58.135 | 56.656 | 2.9 | 1 1/4 |

| 2-1/2" | 76.1 | 11 | 2.309 | 1.479 | 75.184 | 73.705 | 72.226 | 3.5 | 1 1/2 |

| 3" | 88.9 | 11 | 2.309 | 1.479 | 87.884 | 86.405 | 84.926 | 3.5 | 1 1/2 |

| 4" | 114.3 | 11 | 2.309 | 1.479 | 113.030 | 111.551 | 110.072 | 3.5 | 1 1/2 |

| 5" | 139.7 | 11 | 2.309 | 1.479 | 138.430 | 136.951 | 135.472 | 3.5 | 1 1/2 |

| 6" | 165.1 | 11 | 2.309 | 1.479 | 163.83 | 162.351 | 160.872 | 3.5 | 1 1/2 |

BSPP (G) thread dimension

| Pipe size | Thread number in 25.4mm | Thread pitch (P) | Thread height (h) | Diameter at gauge plane | Tolerances on pitch diameter | ||||

|---|---|---|---|---|---|---|---|---|---|

| Major gauge diameter (d=D) | Pitch (d₂=D₂) | Minor (d₁=D₁) | Internal thread TD2* | ||||||

| Lower deviation | Upper deviation | ||||||||

| (inch) | (mm) | (no.) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) |

| 1/4" | 13.5 | 19 | 1.337 | 0.856 | 13.157 | 12.301 | 11.445 | 0 | + 0.125 |

| 3/8" | 17.2 | 19 | 1.337 | 0.856 | 16.662 | 15.806 | 14.950 | 0 | + 0.125 |

| 1/2" | 21.3 | 14 | 1.814 | 1.162 | 20.955 | 19.793 | 18.631 | 0 | + 0.142 |

| 3/4" | 26.9 | 14 | 1.814 | 1.162 | 26.441 | 25.279 | 24.117 | 0 | + 0.142 |

| 1" | 33.7 | 11 | 2.309 | 1.479 | 33.249 | 31.77 | 30.291 | 0 | + 0.180 |

| 1-1/4" | 42.4 | 11 | 2.309 | 1.479 | 41.910 | 40.431 | 38.952 | 0 | + 0.180 |

| 1-1/2" | 48.3 | 11 | 2.309 | 1.479 | 47.803 | 46.324 | 44.845 | 0 | + 0.180 |

| 2" | 60.3 | 11 | 2.309 | 1.479 | 59.614 | 58.135 | 56.656 | 0 | + 0.180 |

| 2-1/2" | 76.1 | 11 | 2.309 | 1.479 | 75.184 | 73.705 | 72.226 | 0 | + 0.217 |

| 3" | 88.9 | 11 | 2.309 | 1.479 | 87.884 | 86.405 | 84.926 | 0 | + 0.217 |

| 4" | 114.3 | 11 | 2.309 | 1.479 | 113.030 | 111.551 | 110.072 | 0 | + 0.217 |

| 5" | 139.7 | 11 | 2.309 | 1.479 | 138.430 | 136.951 | 135.472 | 0 | + 0.217 |

| 6" | 165.1 | 11 | 2.309 | 1.479 | 163.83 | 162.351 | 160.872 | 0 | + 0.217 |

D = d; major diameter of the internal thread

D₁ = D - 1.280 654 P = d₁; minor diameter of the internal thread

D₂ = D - 0.640 327 P = d₂; pitch diameter of the internal thread

d = Major diameter of the internal thread

d₁ = d - 1.280 654 P = d₁; minor diameter of the external thread

d₂ = d - 0.640 327 P = d₂; pitch diameter of the external thread

H = Height of the fundamental triangle of the thread

h = Height of the thread profile with rounded crests and roots

P = Pitch

r = Radius of rounded crests and roots

* For more dimensions of thread please refer to ISO 228-1 table 1.

BSPT

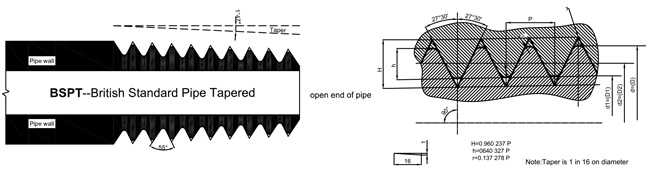

British Standard Pipe Taper Thread (BSPT) has been adopted internationally as a standard scale used in plumbing fittings, and it is defined by BS EN 10226-1, BS EN 10226-2, and ISO 7-1 (GB/T 7306.1, GB/T 7306.2).

BSPT thread has Whitworth thread form (rounded peaks and valleys) with thread angle 55° and tapered thread 1°47’.

BSPT thread dimension

| Pipe size | Thread number in 25.4mm |

Thread pitch (P) |

Thread height (h) |

Diameter at gauge plane * | |||

|---|---|---|---|---|---|---|---|

| Major gauge diameter (d=D) |

Pitch (d2=D2) |

Minor (d1=D1) |

|||||

| (inch) | (mm) | (no.) | (mm) | (mm) | (mm) | (mm) | (mm) |

| 1/4" | 13.5 | 19 | 1.337 | 0.856 | 13.157 | 12.301 | 11.445 |

| 3/8" | 17.2 | 19 | 1.337 | 0.856 | 16.662 | 15.806 | 14.95 |

| 1/2" | 21.3 | 14 | 1.814 | 1.162 | 20.955 | 19.793 | 18.631 |

| 3/4" | 26.9 | 14 | 1.814 | 1.162 | 26.441 | 25.279 | 24.117 |

| 1" | 33.7 | 11 | 2.309 | 1.479 | 33.249 | 31.770 | 30.291 |

| 1-1/4" | 42.4 | 11 | 2.309 | 1.479 | 41.910 | 40.431 | 38.952 |

| 1-1/2" | 48.3 | 11 | 2.309 | 1.479 | 47.803 | 46.324 | 44.845 |

| 2" | 60.3 | 11 | 2.309 | 1.479 | 59.614 | 58.135 | 56.656 |

| 2-1/2" | 76.1 | 11 | 2.309 | 1.479 | 75.184 | 73.705 | 72.226 |

| 3" | 88.9 | 11 | 2.309 | 1.479 | 87.884 | 86.405 | 84.926 |

| 4" | 114.3 | 11 | 2.309 | 1.479 | 113.030 | 111.551 | 110.072 |

| 5" | 139.7 | 11 | 2.309 | 1.479 | 138.430 | 136.951 | 135.472 |

| 6" | 165.1 | 11 | 2.309 | 1.479 | 163.830 | 162.351 | 160.872 |

D = d; major diameter of the internal thread

D₁ = D - 1.280 654 P = d₁; minor diameter of the internal thread

D₂ = D - 0.640 327 P = d₂; pitch diameter of the internal thread

d = Major diameter of the internal thread

d₁ = d - 1.280 654 P = d₁; minor diameter of the external thread

d₂ = d - 0.640 327 P = d₂; pitch diameter of the external thread

H = Height of the fundamental triangle of the thread

h = Height of the thread profile with rounded crests and roots

P = Pitch

r = Radius of rounded crests and roots

* For more dimensions of thread please refer to BS EN 10226-1 table 1, BS EN 10226-2 table 1 and ISO 7-1 table 1.

NPT

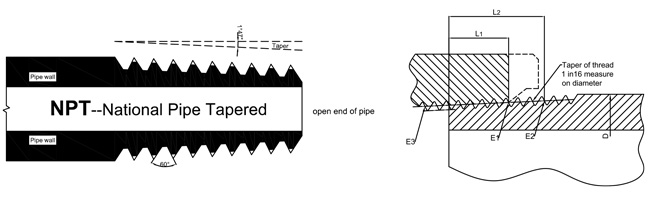

National Pipe Thread Taper (NPT) is a US standard for tapered threads used to join pipes and fittings, and it is defined by ANSI/ASME standard B1.20.1 (GB/T 12716).

It has a Sellers thread form (flattened peaks and valleys) with thread angle 60° and tapered thread 1°47’.

It has a Sellers thread form (flattened peaks and valleys) with thread angle 60° and tapered thread 1°47’.

NPT thread dimension

| Pipe size | Thread number | Thread pitch | Thread height | Hand-tight engagement * | |||

|---|---|---|---|---|---|---|---|

| D | No. | P | h | Length | Threads | Diameter | |

| (inch) | (mm) | (no. / inch) | (inch) | inch | (L1, inch) | (no.) | (E1, inch) |

| 1/4" | 13.7 | 18 | 0.05556 | 0.04444 | 0.2278 | 4.10 | 0.49163 |

| 3/8" | 17.1 | 18 | 0.05556 | 0.04444 | 0.240 | 4.32 | 0.62701 |

| 1/2" | 21.3 | 14 | 0.07143 | 0.05714 | 0.320 | 4.48 | 0.77843 |

| 3/4" | 26.7 | 14 | 0.07143 | 0.05714 | 0.339 | 4.75 | 0.98887 |

| 1" | 33.4 | 11.5 | 0.08696 | 0.06957 | 0.400 | 4.60 | 1.23863 |

| 1-1/4" | 42.2 | 11.5 | 0.08696 | 0.06957 | 0.420 | 4.83 | 1.58338 |

| 1-1/2" | 48.3 | 11.5 | 0.08696 | 0.06957 | 0.402 | 4.83 | 1.82234 |

| 2" | 60.3 | 11.5 | 0.08696 | 0.06957 | 0.436 | 5.01 | 2.29627 |

| 2-1/2" | 73.0 | 8 | 0.12500 | 0.10000 | 0.682 | 5.46 | 2.76215 |

| 3" | 88.9 | 8 | 0.12500 | 0.10000 | 0.766 | 6.13 | 3.3885 |

| 4" | 114.3 | 8 | 0.12500 | 0.10000 | 0.844 | 6.75 | 4.38712 |

| 5" | 141.3 | 8 | 0.12500 | 0.10000 | 0.937 | 0.94 | 5.44929 |

| 6" | 168.3 | 8 | 0.12500 | 0.10000 | 0.958 | 7.66 | 6.50597 |

Note:

L1 = length of hand-tight engagement between internal and external threads.

E1 = basic pitch diameter at plane of hand-tight engagement length (L1), external thread, and large end of internal thread.

L2 = length of effective thread, external thread. Equal to L1 plus wrench make-up threads.

E2 = basic pitch diameter at plane of effective thread length (L2), external thread.

E3 = basic pitch diameter at plane of wrench-tight engagement.

* For more dimensions of thread please refer to ASME B1.20.1 table 2.

E1 = basic pitch diameter at plane of hand-tight engagement length (L1), external thread, and large end of internal thread.

L2 = length of effective thread, external thread. Equal to L1 plus wrench make-up threads.

E2 = basic pitch diameter at plane of effective thread length (L2), external thread.

E3 = basic pitch diameter at plane of wrench-tight engagement.

* For more dimensions of thread please refer to ASME B1.20.1 table 2.

Threads connection

For BSPP pressure-tight connection, the threads are parallel internal and taper external and parallel (Rp x R1).

For BSPP not pressure-tight connection, the threads are parallel internal and parallel external (G x G).

If assemblies with such threads must be made pressure-tight, this should be effected by compressing two tightening surfaces outside the threads, and by interposing an appropriate seal.(Such as adding O-ring).

If assemblies with such threads must be made pressure-tight, this should be effected by compressing two tightening surfaces outside the threads, and by interposing an appropriate seal.(Such as adding O-ring).

For BSPT connection, the threads are taper internal and taper external (Female BSPT x Male BSPT).

For NPT connection, the threads are taper internal and taper external (Female NPT x Male NPT).